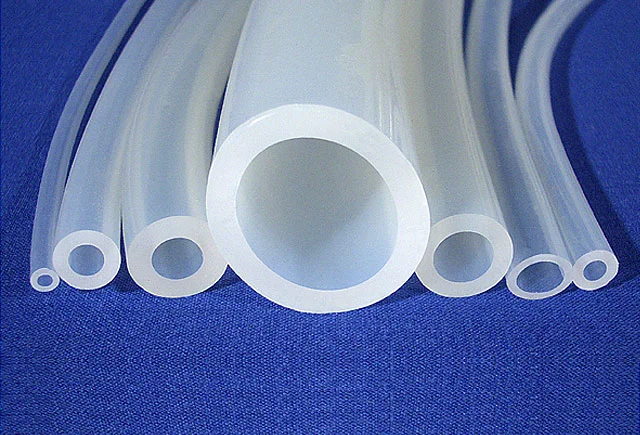

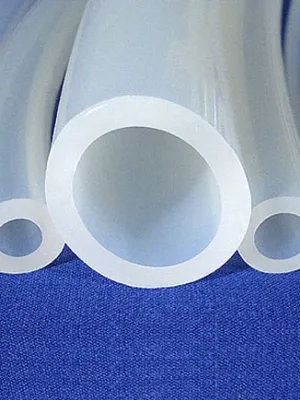

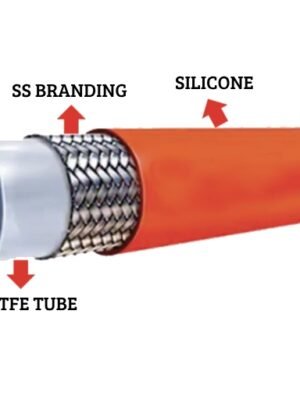

Comprehensive range of silicone tubing, manufactured busing latest Extrusion Technology & Advanced Grade Platinum Cured Silicone with bore sizes from 0.5mm up to 150 mm, meets the demands of practically regulatory market application. Better fluid transfer characteristics compare to peroxide silicone tubing. Platinum cured silicone tubing designed for peristaltic pump and fluid transfer in pharmaceutical and biotech applications Free of any heavy

metals & hazardous substances. We offers a wide selection of approved material for use specifically within hygiene critical applications including FDA, CFR and USP Class V.I

Platinum Based Cure system

This is an advanced curing system. Platinum complex is the cure initiator and accelerator

Advantages:

- Silicone tubing can be manufactured with high transparency

- These kind of tubing have no contamination due to substrate.

- Silicone tubing has flame retardant properties, which makes is excellent for anesthetic applications

- FDA compliant and recommended for food and medical usage.

Disadvantages:

- Comparatively costlier than peroxide based silicone tubing

- Physical properties are not as good as peroxide based tubing

Main properties of our Transparent Silicone Tubing

- Temperature resistance from -30°C to 220°C

- Chemical resistance to a range of fluids and solvent

- UV resistance

- Corona discharge resistance

- FDA compliant and Food grade tubing