Key Features:

- High-Quality Material Composition

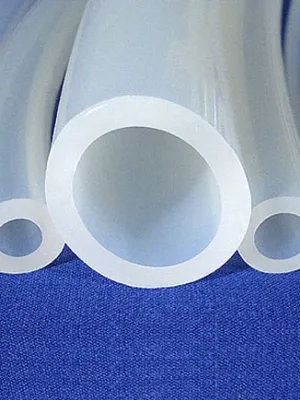

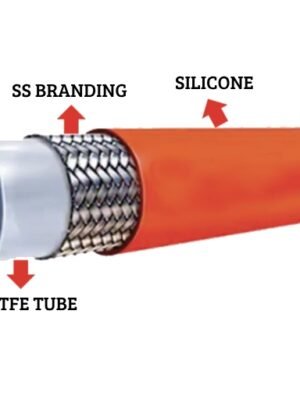

- Silicone Peroxide Cured Transparent Tube: Offers excellent heat resistance, flexibility, and long-term durability.

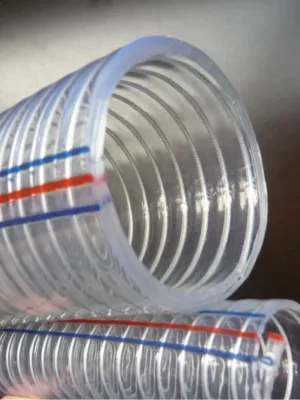

- Thermoplastic Tube: Provides enhanced chemical resistance and mechanical strength while being lightweight and easy to handle.

- Superior Transparency & Clarity

- Both variations feature a clear and smooth bore, allowing real-time monitoring of fluid flow for process control and safety.

- Temperature & Chemical Resistance

- Withstands a wide temperature range from -50°C to +200°C, ensuring reliability in extreme conditions.

- Resistant to ozone, UV exposure, and various chemicals, ensuring longevity and compatibility with different applications.

- Enhanced Flexibility & Durability

- Designed to be kink-resistant and highly flexible, enabling easy installation and maneuverability.

- Suitable for high-pressure and vacuum applications, depending on the variation selected.

- Compliant with Global Industry Standards

- Manufactured in accordance with FDA 21 CFR 177.2600, USP Class VI, and cGMP guidelines, ensuring safe usage in pharmaceutical, food, and medical environments.

Applications:

- Pharmaceutical & Biotech: Ideal for sterile liquid transfer, drug manufacturing, and laboratory use.

- Food & Beverage Processing: Suitable for dairy, brewery, and beverage production.

- Medical & Healthcare: Used in peristaltic pumps, surgical equipment, and fluid handling systems.

- Industrial & Chemical Processing: Provides safe and durable fluid transfer in aggressive chemical environments.

Available Variants & Customization

- Silicone Peroxide Cured Transparent Tube: Recommended for applications requiring high-temperature resistance and flexibility.

- Thermoplastic Tube: Ideal for scenarios needing enhanced chemical resistance and mechanical strength.

- Available in various sizes, thicknesses, and pressure ratings to suit diverse industry requirements.