- Home

- Our Products

- Tubes

- Silicon Tube

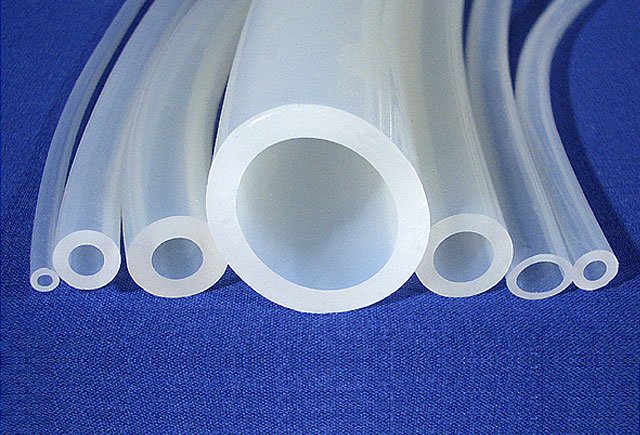

Silicon Tube

02 Details

Transparent Silicone Tubing are cured using following two types of cure systems:

Peroxide based cure system

Advantages:

- Peroxide based cure systems were traditional types of cure systems.

- Peroxide based silicone curing is cheaper

- Imparts better physical properties than platinum based silicone

Disadvantages:

- Product post curing is necessary to remove unreacted peroxide traces from the surface.

- Extractables may have peroxide traces.

Platinum Based Cure system

This is an advanced curing system. Platinum complex is the cure initiator and accelerator

Advantages:

- Silicone tubing can be manufactured with high transparency

- These kind of tubing have no contamination due to substrate.

- Silicone tubing has flame retardant properties, which makes is excellent for anesthetic applications

- FDA compliant and recommended for food and medical usage.

Disadvantages:

- Comparatively costlier than peroxide based silicone tubing

- Physical properties are not as good as peroxide based tubing

Main properties of our Transparent Silicone Tubing

- Temperature resistance from -30°C to 220°C

- Chemical resistance to a range of fluids and solvent

- UV resistance

- Corona discharge resistance

- FDA compliant and Food grade tubing