Key Features:

- PTFE (Polytetrafluoroethylene) Inner Lining

- High-purity PTFE lining provides superior chemical resistance, making it ideal for handling corrosive fluids, solvents, and high-purity liquids.

- Ensures a smooth, non-stick surface to prevent contamination and facilitate easy cleaning.

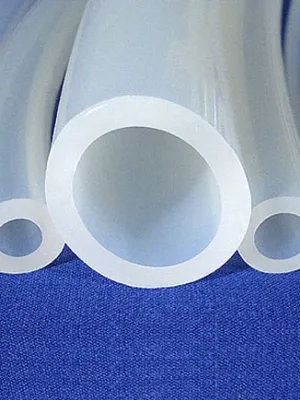

- Platinum-Cured Silicone Outer Layer

- The platinum-cured silicone ensures biocompatibility, non-toxicity, and flexibility, making it suitable for sterile applications.

- Resistant to UV, ozone, and bacterial growth, maintaining hygiene in critical environments.

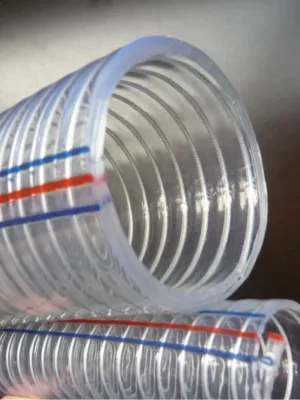

- SS 304 Stainless Steel Braiding

- High-strength SS 304 braiding enhances pressure resistance, tensile strength, and durability.

- Provides excellent mechanical protection, preventing hose expansion and ensuring stability under vacuum or high-pressure conditions.

- Temperature & Chemical Resistance

- Withstands extreme temperatures ranging from -60°C to +260°C, ensuring reliability in harsh industrial environments.

- Resistant to a wide range of acids, alkalis, and aggressive chemicals, extending product lifespan.

- Flexible, Lightweight & Kink-Resistant Design

- The combination of PTFE lining, SS 304 braiding, and an outer cover ensures excellent flexibility and kink resistance, even in dynamic applications.

- Meets Industry Standards

- Complies with FDA 21 CFR 177.1550, USP Class VI, and cGMP requirements for safe use in pharmaceutical, food, and medical applications.

Applications:

- Pharmaceutical & Biotech Industry: Ideal for sterile liquid transfer, vaccine production, and bioreactors.

- Food & Beverage Processing: Used in dairy, brewery, and beverage production for hygienic fluid handling.

- Chemical & Industrial Applications: Safely handles aggressive solvents, acids, and alkalis in process industries.

- Medical & Healthcare: Suitable for medical devices, dialysis equipment, and surgical applications.

- High-Temperature & High-Pressure Applications: Perfect for steam sterilization, autoclaving, and critical fluid transfer.